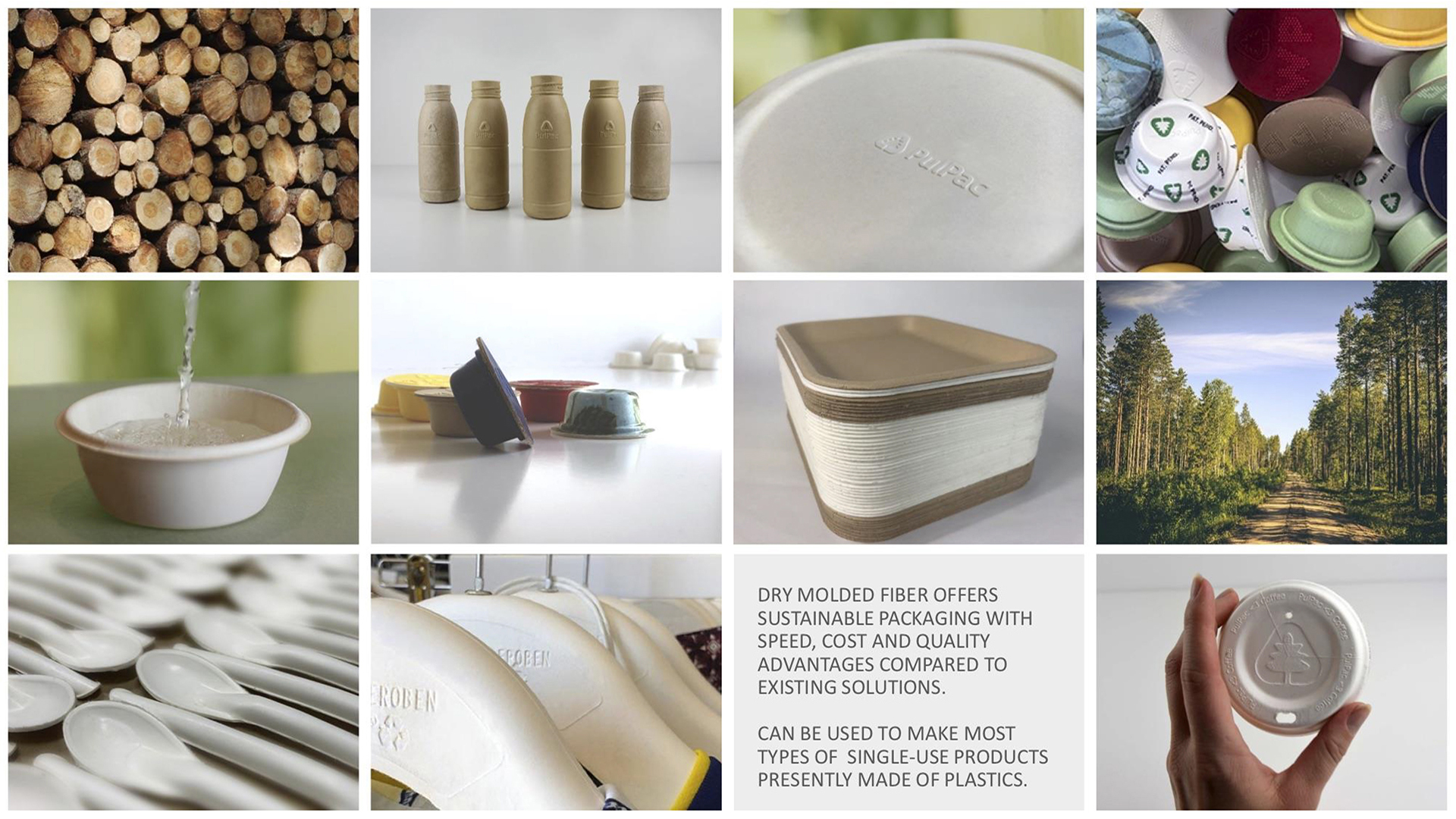

ThermoFibre™ Polyco Healthline's pulp division, provide bespoke packaging solutions to a variety of industries

We specialise in consumer and industrial packaging as well as long shelf-life barrier packaging, particularly food trays.

With our own pulp development lab and product design team, we assist companies in converting their existing packaging to a more sustainable fibre alternative.

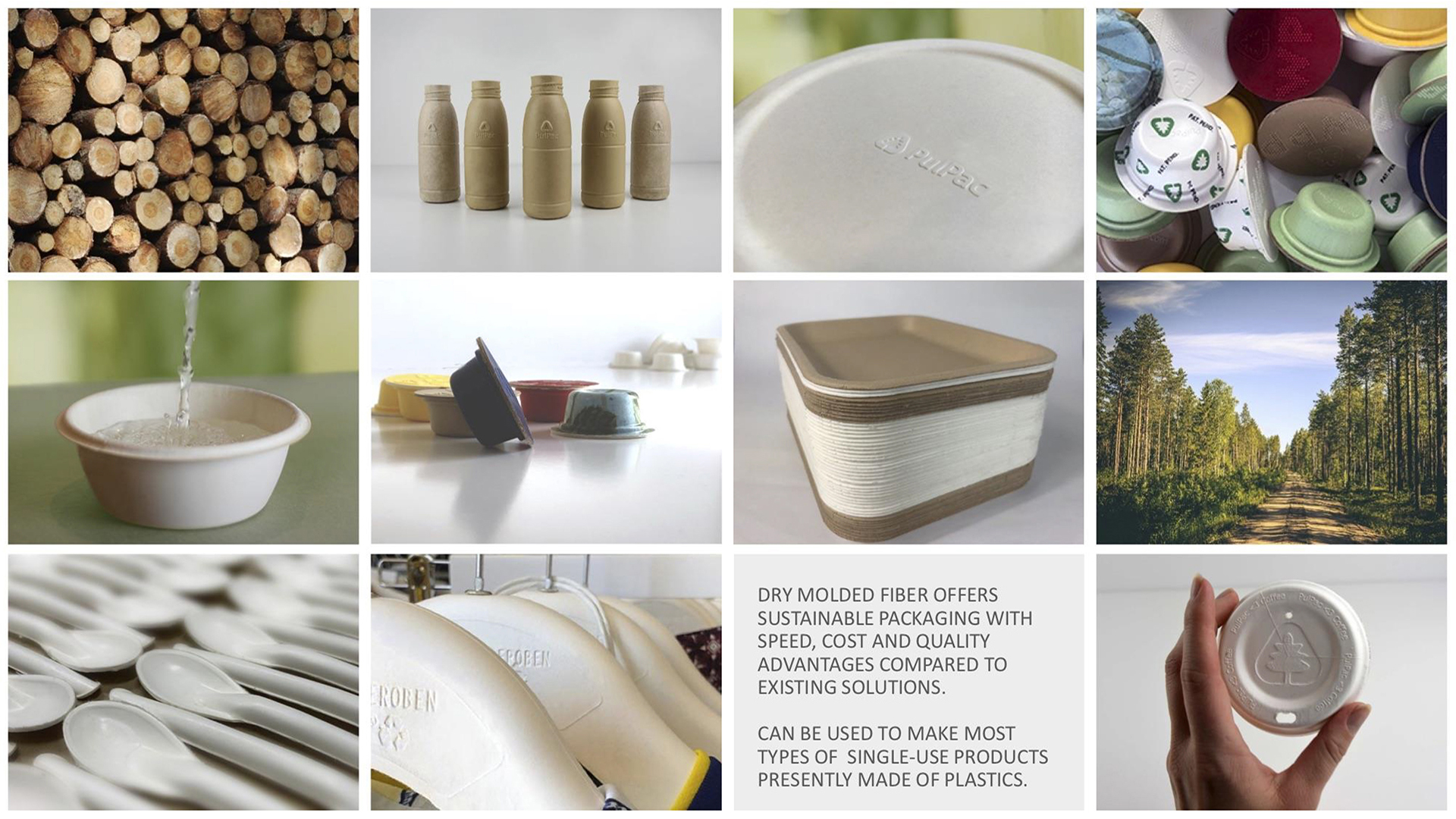

As well as our own pulp development lab, we are exclusively using PulPac which is a first in the UK. PulPac is a ground breaking manufacturing technology for low cost, high performance fibre-based packaging and single-use products. By pioneering the technology of cellulose moulding we enable our customers to replace single-use plastics with a sustainable and cost competitive alternative.

And that is the future. Dry moulded fibre offers sustainable packaging with speed, cost and quality advantages compared to existing solutions...

What is Dry Moulded Fibre

- DMF is made from compressing dry fiber with a light moisture content (5%) and heat under very high pressure. Creating hydrogen bonds between the fibres; surplus moisture is lost in the atmosphere.

- Each tool impression is subjected to over 12 tonnes of compressive force. In wet pulp each part experiences much less pressure.

- The process uses very low energy compared to conventional pulp and plastic thermoforming.

- Cycle times are around the 3.5 seconds range compared to 30 seconds plus for thermoformed pulp.

Innovation is key to our developments and ThermoFibre has over 15 patents relating to pulp products and processes.

For more information on how we can provide a pulp solution for you.